- Home

- >

- News

- >

- Industry News

- >

- Quick Opening Closure Basket filter Professional Manufacture

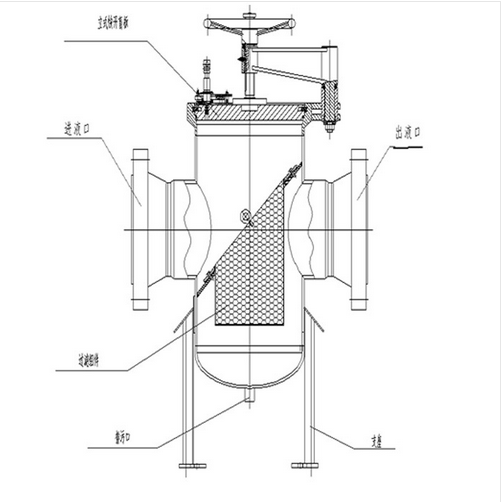

Quick Opening Closure Basket filter Professional Manufacture

Basket filter

Basket filter consist of nozzle, shell,fiter basket,quick opening closure etc. After inlet of liquid through the filter into the filter basket and blocked from solidparticles inside the filter basket , and clean fluid through the filter basket flow out .when cleaning is required , unscrew drain plug at the bottom of the shell , drain the fluid, open the quick opening clousre and cleanig the strainer mesh before reload .Therefore , it is easy to use and maintenance.

Specification

| Size | Customized |

| Design Pressure | Up to 16 Mpa |

| Precision | 0.5-100um |

| Filtration Efficient | 99.99% |

| Diameter Range | DN15-DN1000 |

| Main Body | CS & SS |

| Filter Type | Basket Filter |

| Medium | Crude Oil |

| Design Code | ASMEVIII-1 |

|  |

Carbon steel filter

Carbon steel filter manufacturer precision filter still has huge research and development space. The advantage of precision filter is that it can more effectively remove impurities in liquid. The construction of direct drinking water in today's market is constantly developing and developing. Direct drinking water has great potential, which depends on various types of precision filters. To distinguish a concept, precision filters are not only used in industrial production, food, but also in drinking water in daily life. Water filtering through precision filters is also the core component of some filters. It can not only intercept impurities in water, including particulate matter, suspended matter, but also some impurities in the air. It can also be combined with other automatic cleaning components to remove pollution, prevent corrosion and bacteria. The new type of water filter has overcome the problems of small capacity of traditional filters and impurities blocking the filter screen. Precision filters play an important role in the development of water treatment.

Cleaning

1. The core part of the filter is the filter core, which is composed of the filter frame and stainless steel wire mesh. The stainless steel wire mesh is a vulnerable part and needs special protection.

2. When the filter works for a period of time, some impurities are deposited in the filter core. When the pressure drop increases and the flow rate decreases, impurities in the filter core need to be removed in time.

3. When cleaning impurities, pay special attention to the stainless steel wire mesh on the filter core can not be deformed or damaged. Otherwise, the purity of the filtered media can not meet the design requirements, and the compressor, pump, instrument and other equipment will be damaged.

4. If stainless steel wire mesh is found to be deformed or damaged, it should be replaced immediately.