- Home

- >

- Products

- >

- Pigging Equipment

- >

- Pig Launcher Receiver

- >

- Normal Pig Scrapper Launcher Receiver

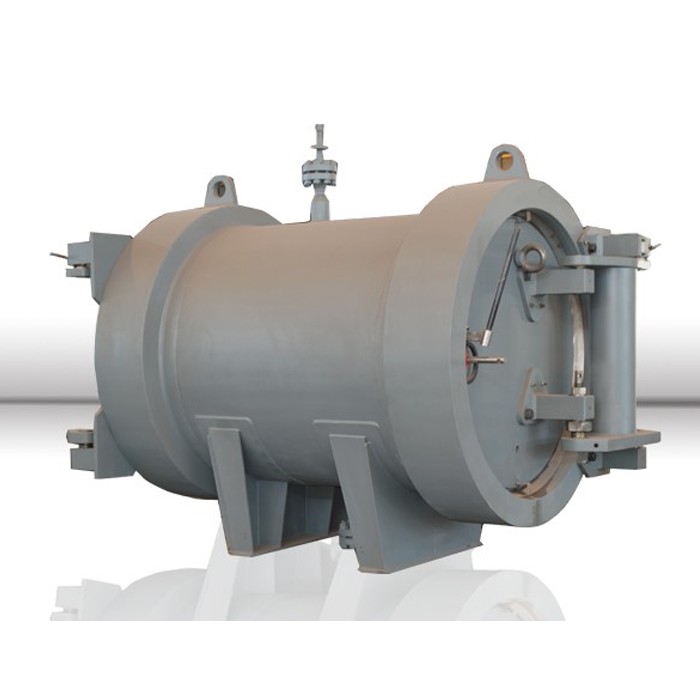

Normal Pig Scrapper Launcher Receiver

Brand :YY

Product origin :LIAONING,CHINA

Delivery time :Normally 30~60 days after order award

Supply capacity :10 sets per month

Pig receiver & launcher is the main process equipment of petrochemical pipeline station, its basic functions for pigging is capable of sending and receiving of pipeline cleaner. According to the different applicable objects are divided into suitable for Pipeline Pigging for ordinary pig receiver & launcher or standard pig receiver & launcher; suitable for pipeline detection for intelligent pig receiver & launcher or lengthened pig cylinder, standard pig receiver & launcher and intelligent pig receiver & launcher the main difference is length of the barrel.

Pig receiver & launcher is mainly composed of: Quick Opening Closure and barrel(major barrel & minor barrel), reducer, saddle and vent valve, drain valve, pressure gauge, mechanical ball passage indicator etc.. Under normal circumstances, pig launcher using concentric reducer and pig receiver using eccentric reducer for launch and receive cleaning pig.

Usually, the major barrel length is two times of the pipeline cleaner for pig launcher. Pig receiver need make sure at least can take 2 cleaner at the same period, it means major barrel nearly three times of the major barrel.

The main part of the Pig receiver & launcher:

The main part of the Pig Receiver & Launcher:

The end of the major barrel is provided with a quick opening closure device, which is used for removing the pipe cleaner, and has the characteristics of simple and rapid switch, safe and reliable sealing. A safety interlock device is arranged on the barrel, which can ensure that the device can not be opened under the pressure, thereby ensuring the safety of the equipment and the personnel.

The valve is used to vent pipeline replacement before using pipeline purging and gas, when the pipe cleaning after the pipeline valve is closed, the vent valve opens, the excess gas is discharged to the atmosphere inside the barrel, thereby reducing the pressure of safety interlock device lifting effect.

The discharge valve for discharging dirt, when a lot of dirt in the pipeline lead to blockage of the ball valve, can open the sewage ball valve, thereby ensuring the smooth removal of dirt.

The pressure gauge is used to display the gas pressure inside the launcher, to control it through a needle valve, ensure the safety of.

Mechanical passage ball indicator is installed in the side of the service line, when the pig through, indicating the pig is through.

Bypass ball valve for controlling whether the media is passed from pig launcher and receiver.

Main features:

We are using the most advanced Lock ring type quick opening closure, it is safe and reliable, with safety self-locking device, when the pipeline still have some pressure, quick opening closure can not be opened, can avoid misoperation, flexible opening and closing, convenient and labor.

Quick Opening Closure sealed with lip rubber gasket with self-sealing.

This equipment is equipped with accurately judge whether the pig cleaner has been sending or receiving the pig cleaner indicator, and according to the requirements of users can choose with welding pointer or non-contact mechanical ball passage indicator.

The device designed with enough safety margin, and provide a more reliable security assurance.

The barrel body have a balance pipe for keep the pressure equilibrium before and after the cleaner. In case pipeline cleaner crash the spool of ball valve.

Technical Parameter:

Design pressure: PN1.6-16.0Mpa.

Diameter: DN150~DN2500mm.

Test pressure: 1.5 times of the design pressure, air tightness test is equivalent to design pressure.

Corrosion margin: minimum 2mm.

The earthquake intensity of crack: 7°.

Applicable medium: crude oil, refined oil (gasoline, diesel), gas, water.

Design and manufacturing basis: ASME VIII-1, ASME31.3, 31.4 & 31.8.