- Home

- >

- Products

- >

- Station Equipment

- >

- Heat Exchanger

- >

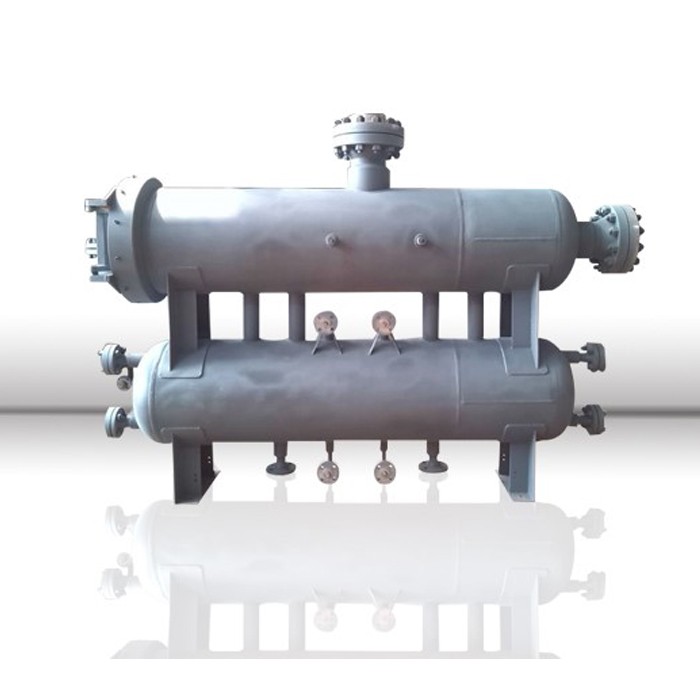

- Double Pipe High Pin Heat Exchanger

Double Pipe High Pin Heat Exchanger

Brand :YY

Product origin :LIAONING,CHINA

Delivery time :Normally 30~60 days after order award

Supply capacity :3000 tons per year

The hairpin heat exchanger is a U-tube heat exchanger with separate shells for both tube bundles (straight part of the tubes).

Independent tubesheets for high-temperature differences, thermal shock and cycling. Moveable support brackets with slots for shell expansion and flexibility in installation.The reversal chamber over the U-tube bends can be welded or flanged.

vortex hot film heat exchanger membrane vortex hot film heat transfer using the

latest technology, to increase the heat transfer effect by changing the fluid motion

state, when the medium through the vortex tube surface, powerful flush the pipe

surface, thus improve the thermal efficiency. Up to 10000 °C w/m2 .

At the same time the structure to achieve the corrosion resistance, resistance to

high temperature, high pressure, anti scaling function. Other types of heat exchanger

fluid channel as fixed direction flow form, formed on the surface of heat exchange

tube flow around, convective heat transfer coefficient decrease.

Characteristic:

Reliable Closures for design pressures up to 15,000 psi (1055 kg/cm2)

Independent tubesheets for high-temperature differences, thermal shock and cycling.

External Split Rings do not contact Shellside fluid.

All connections on the same end for ease of piping.

Moveable Support Brackets with slots for shell expansion and flexibility in installation.

Durable all Welded baffle cage construction

All Bolting is external.

Large Radius U-bends for ease of cleaning and effective thermal expansion (no expansion joints).

Description:

Design code: ASME VIII-1, PD5500, JIS,API660,TEMA

Quality Rule: DNV, NORSKE, ISO 9001:2008

Thermal Calculation: HTRI software

Mechanical Calculation: PVElite software

Special Material: Ti, Copper Nickle, Monel, Hastelloy

Features:

High-efficiency heat transfer;

Processing of tube plates and baffle plates using the CNC Machining Center;

Professional welding;

Flexible hydraulic expansion

After-sales service

We promise that:

We answer and solve your questions and consult within 24 hours.

We arrive to the domestic job site within 48 hours from the time you asked.

Overseas job site service available.

Service telephone: +86-24-88256563